|

|

Mark-10 M7I Professional Force / Torque Indicator

Price: $ 1,740.00

14,000 Hz sampling rate

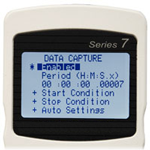

Continuous/single data point capture for 5,000 readings, with statistics

Footswitch command string

Break detection and auto output/zero

The Mark-10 Series-7I Professional Force / Torque Indicator is designed to work with a wide range of our remote force and torque sensors. With exclusive Plug & TestTM technology, all calibration and configuration data is saved within the sensor's smart connector, not the indicator, allowing for true interchangeability. In addition, all sensors are fully compatible with other indicators. The Mark-10 Series-7i Professional Force and Torque Indicator features an industry-leading sampling rate of 14,000 Hz, producing reliable results for extremely quick-action tests. In addition to the 5i indicator's functions, the Series 7i features high speed continuous data capture and storage, with memory for up to 5,000 readings, at an acquisition rate of up to 14,000 Hz. The Series 7i also features programmable footswitch sequencing, break detection, and 1st / 2nd peak detection. Coefficient of friction unit of measurement and a user-defined unit of measurement add flexibility for specialized applications. For productivity enhancement, the indicator also features automatic data output, data storage, and zeroing functions upon the completion of break detection, averaging, external trigger, and 1st / 2nd peak detection. The Series 7i interfaces with our motorized test stands to permit functions such as break testing, dynamic load holding, PC control capability, and more. The included MESURTM Lite data acquisition software tabulates continuous or single point data. Data saved in the indicator's memory can also be downloaded in bulk. One-click export to Excel easily allows for further data manipulation.

Kit Contents

- Mark-10 Series 7i Professional Force / Torque Indicator

- Carrying case

- USB cable

- AC adapter

- Battery

- Resource CD

- Three (3) year warranty

|  |

Features

- Interchangeable force and torque sensors through Plug & Test technology (sensors are sold separately)

- Sensor password protection, for preventing use of an unauthorized sensor

- Password protection for individual keys and calibration

- High-speed 14,000 Hz sampling rate

- Continous data capture of up to 5,000 data points, at up to 14,000 Hz, downloadable to a PC

- Individual data point memory for up to 5,000 readings, downloadable to a PC

- USB, RS-232, Mitutoyo, and analog outputs

- Sample break detection with auto functions, including stopping movement of a Mark-10 motorized test stand

- Automatic output / data storage / zeroing upon various event completions

- 1st / 2nd peak detection

- 5 units of measurement, plus Coefficient of Friction and user-defined unit with configurable name

- Footswitch function configure up to 3 functions per footswitch activation

- Programmable set points, with indicators and outputs

- Averaging mode calculates average readings over time

- External trigger mode for switch contact testing or remotely stopping display update

- Password protection, configurable for individual keys and calibration

Specifications

| Accuracy | 0.1% of full scale + sensor | | Sampling rate | 14,000 Hz | | Power | AC or rechargeable battery. Multi-step low battery indicator is displayed, gauge shuts off automatically when power is too low. | | Battery Life | Backlight on:up to 7 hours of continuous use

Backlight off:up to 12 hours of continuous use | | Outputs | USB / RS-232:Configurable up to 115,200 baud. Includes Gauge Control Language 2 for full computer control.

Mitutoyo (Digimatic):Serial BCD suitable for all Mitutoyo SPC-compatible Devices.

Analog:1V DC, 2% of full scale at capacity.

General purpose:Three open drain outputs, one input.

Set points:Three open drain lines.

| | Configurable Settings | Digital filters, outputs, automatic output (via USB/RS-232), automatic shutoff, default settings, averaging mode, external trigger, passwords, key tones, audio alarms, backlight, calibration | | Safe overload | 150% of full scale (display shows "OVER" at 110% and above) | | Weight | Weight: 0.7 lbs (0.3 kg) | | Warranty | 3 years |

Specialized Functions

The 7i indicator features several functions typically found in more complex instruments, such as materials testers, data acquisition systems, and PLCs. The following unique features are highlighted: | High Speed Data Capture & Storage Series 7 can capture and store up to 5,000 continuous data points at a rate of up to 14,000 readings per second. This unique function is ideal for capturing switch activation forces, sharp breaks, and other short-duration applications. Configurable start and stop triggers are provided. The data acquisition rate is variable and can be slowed to also capture longer events, such as structure relaxation, material expansion, and others. Data from the storage buffer can be exported to data collection software such as MESURgauge for further analysis and graphing. Using a Series 7 gauge could replace cumbersome and expensive data acquisition hardware and software. |  |

| Footswitch Command String Integrate your footswitch / automation system with a Series 7 gauge to improve testing ergonomics and efficiency; no need for multiple key presses. Up to three steps may be programmed for a single footswitch activation. Select from several commands, including request peak reading, zero the display, save to memory, and others. Time delays can be inserted between each step. |  |

Automatic Data Output / Save / Zero / I/O Pin Toggle

Upon completion of several event types, the Series 7 can perform the following productivity-enhancing functions: - Automatically save the peak reading to memory.

- Transmit the peak reading via USB, RS-232, or Mitutoyo output.

- Zero the display. Toggle an I/O pin, for example to stop movement of an ESM303 test stand.

|  |

Applicable events include: - Sample break detection (also applicable to samples which slip, click, or otherwise reach a peak, then fall).

- Completion of an averaging sequence.

- External trigger (ex. switch activation).

- 1st / 2nd peak capture (ex. tensile testing).

User-defined Unit of Measurement

Series 7 gauges display 6 standard units of measurement. One additional user-defined unit is provided for unique applications. A base unit is specified, along with a multiplier, and 5-character name. Typical applications: |  |

- To measure the torque produced by pressing on a lever in a mechanical assembly, configure the multiplier based on the length of the lever, thereby converting a unit such as N into Ncm.

- To measure the pressure produced by a circular compression plate on a foam sample, configure the multiplier based on the area of the plate, thereby converting a unit such as lbF into psi.

Available Sensors

Related Products

Downloads

|

|

|